-40%

A & B Series Cam Followers Lifters BMC Tappets Super DutyHardness Rc63 Chilled

$ 68.61

- Description

- Size Guide

Description

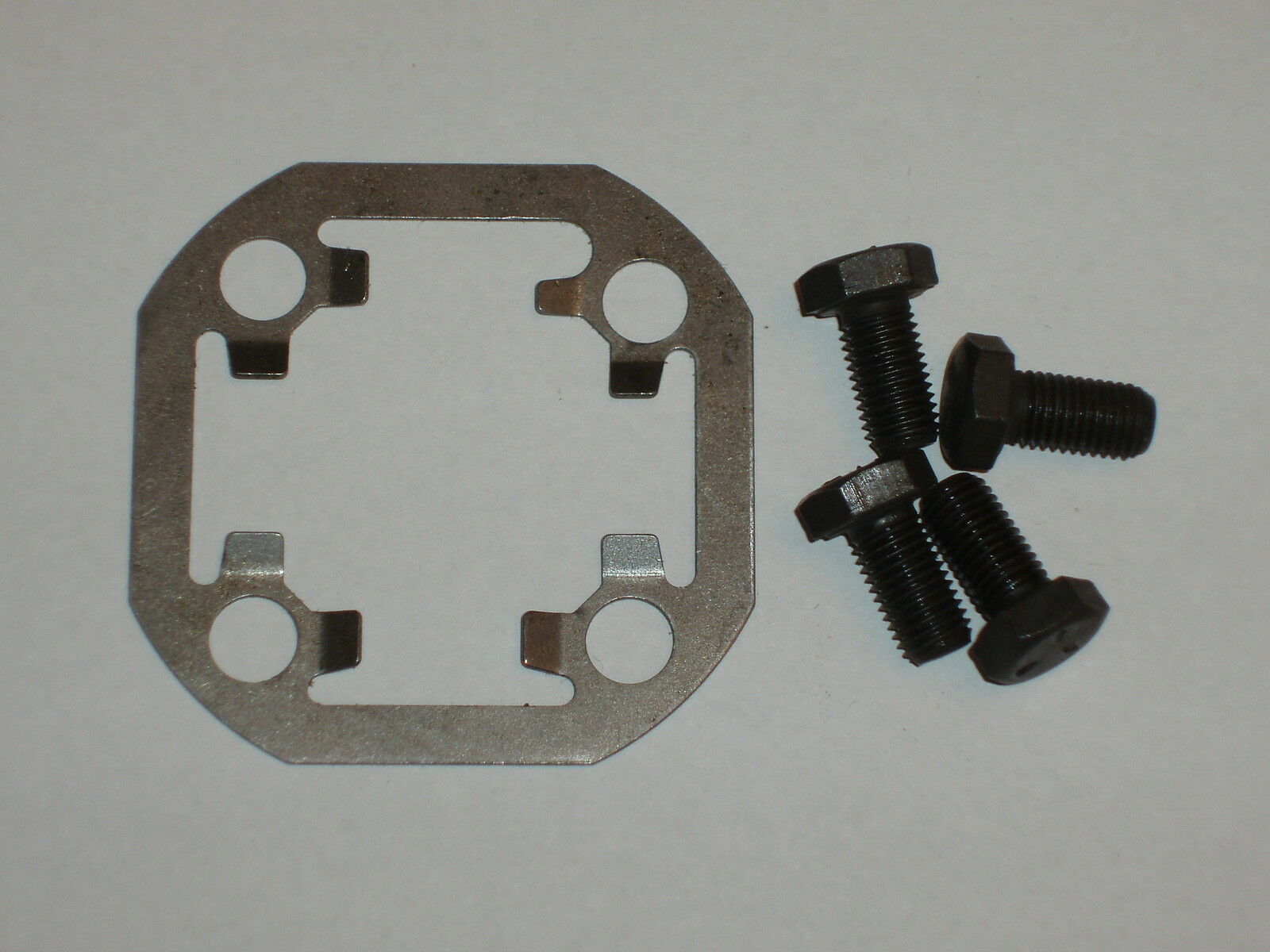

Advanced Performance Technology's New 60+ Cam Follower SeriesThis listing is for a set of 8 Super Duty Chilled Iron Lifters for BMC 'A' & 'B' Series engines.

Our cam followers are manufactured from super duty chilled iron with a manganese phosphate coating for easy break in.

All followers have a face hardness of Rockwell Rc 63 face hardness and weigh only 44 grams.

The side oil hole drains the lifter, and drops oil back on to the lobe to increase lubrication of the lobe as well as reducing follower recipricating weight.

Correct face radius for BMC specification cams so that they match with the lobe taper exactly (this is what ensures that the follower spins correctly. A small detail, but critical!)

Original equipment manufacturer (British Leyland Austin, Morris, MG etc.) # 2A13 These followers have a nominal diameter of 0.812" (13/16") 20.625mm (less required clearance).

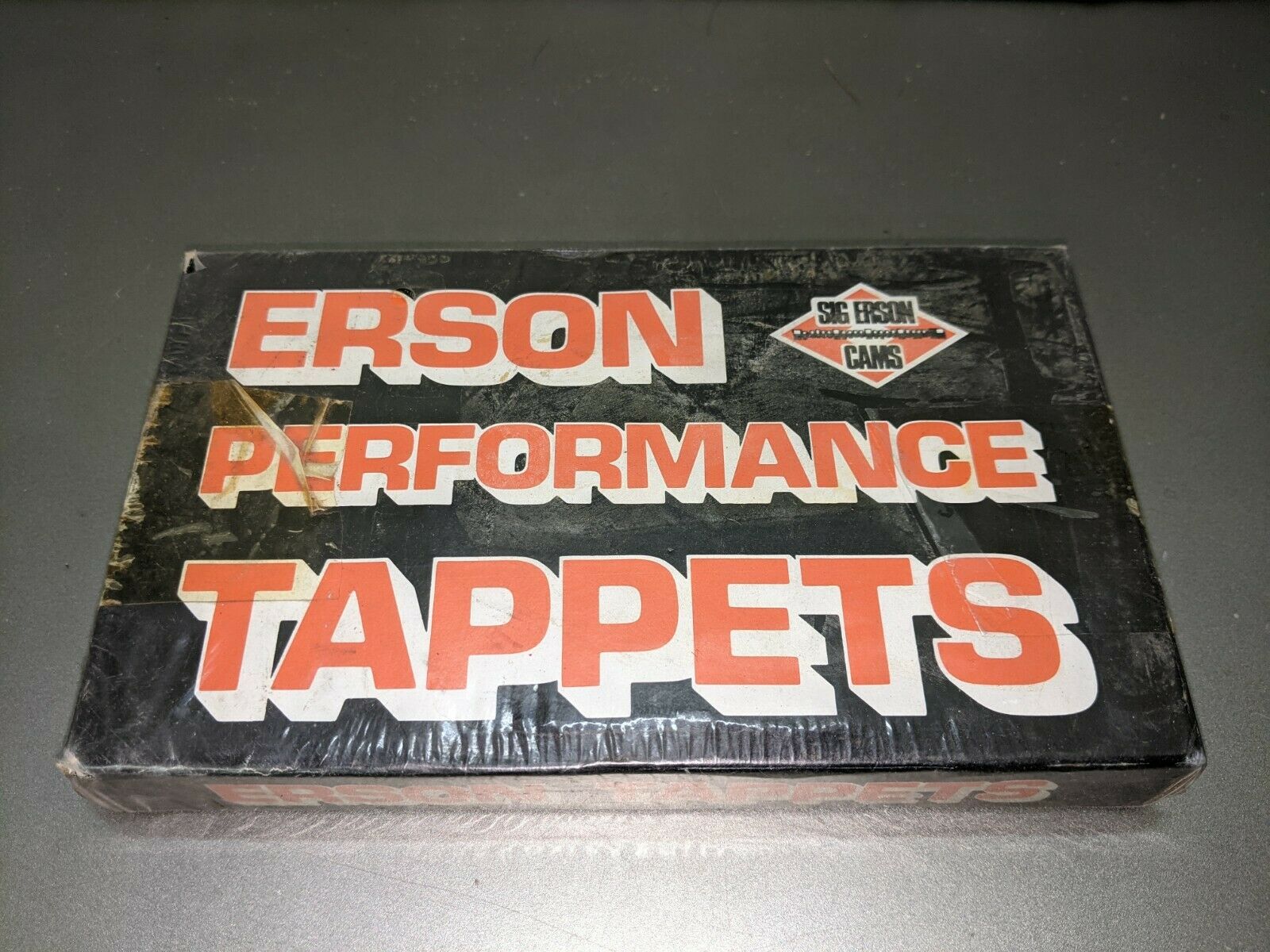

These lifters work great with reground camshafts, although we do recommend that the cam is Plasma Ion Nitride hardened after grinding.

The ultimate is to use them with a heat treated steel billet cam, and the best option here are cams with pressure fed oiling to the lobes as well as the distributor drive gear if available.

Steel billet cams have a surface hardness after heat treatment of Rc57-58 and conventional wisdom has always called for a cam follower that is about 5 points harder. Here it is!

APT cam followers are made from a specially formulated high grade of chilled iron. While the metal chills placed in the mould freeze the internal grain structure into a hard dense surface further heat treatment makes sure that these required properties are distributed evenly across all of the working face that contacts the cam lobe.

Break in, and the use of the correct oils is absolutely vital.

A non synthetic low detergent high ZDDP (over 2000 ppm) formulated for break in should be used, and the manufacturers instructions followed.

After break in use regular or synthetic oil but it must still have ZDDP This has disappeared from the most popular oil (roller cams don't need it).

Do not mix oil with ZDDP additives, its a reciepe for disaster. Most regular oils are loaded with detergent to get the milage between oil changes higher. The problem is detergent is antagonistic to ZDDP, so how can you know how much ZDDP is actually active in your oil mix? YOU CAN'T! For what its worth we use "Lucas" and "Driven".

For a 'flat tappet cam' engine the first 20 min. is critical.

RPM should be kept above 2500 for the first 20 min.

Try to minimise the time grinding the engine over on the starter, there is nothing harder on a cam and followers. If anything "bad" is going to happen it will probably be in the first half hour.

Manufacturer:

A

dvanced

P

erformance

T

echnology

Part No:

CF-04

Free shipping via USPS Priority Mail within the United States.

International orders shipped via USPS Priority Mail International.